Why Are Injection Molds So Expensive?

When sourcing injection molds, many buyers are often surprised by the high price tags. Whether you’re in the automotive, medical, or electronics industry, understanding the cost factors behind injection mold pricing can help you make informed decisions.

At Tianjin Xuansheng Technology Co., Ltd. (TXS), we specialize in high-precision mold manufacturing and cost-effective injection molding solutions. In this article, we’ll break down the key reasons why injection molds are expensive and how you can optimize your investment.

1. Precision Engineering: The Foundation of High-Quality Molds

Injection molds are not off-the-shelf products; they are custom-engineered tools designed for mass production. Achieving micron-level accuracy (±5μm) requires:

✅ State-of-the-art CNC machining – TXS utilizes imported CNC machines, EDM, and precision measuring equipment from Germany, Switzerland, and Japan.

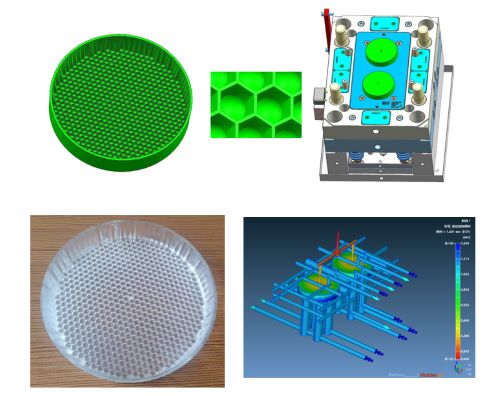

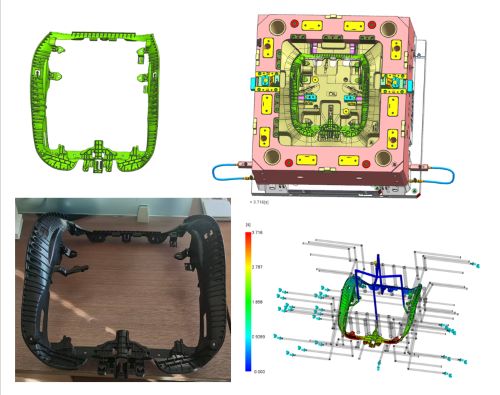

✅ Mold flow simulation – Predicting potential defects like air traps, weld lines, and shrinkage before manufacturing.

✅ Multi-stage quality control – Using CMM metrology equipment from Hexagon to validate dimensional accuracy.

Why it matters? A poorly designed mold results in production defects, costly rework, and high scrap rates. Investing in precision engineering ensures longer mold life and lower total production costs.

2. Premium Materials: Built for Longevity and Durability

Molds must endure high-pressure injection cycles, often running 24/7 for millions of parts. That’s why mold materials need to be high-strength and wear-resistant, such as:

🔹 Hardened steel (H13,S136,1.2083,1.2344,8407) – Ideal for long-life, high-volume production molds.

🔹 Aluminum – Used for prototyping and low-volume production, but less durable.

🔹 Beryllium copper inserts – Improve cooling efficiency and cycle time reduction.

At TXS, we use top-grade steel from Germany and Japan, ensuring our molds have a lifespan of millions of cycles.

3. Advanced Manufacturing Processes: Cutting-Edge Technology

To create complex molds with micron-level accuracy, manufacturers rely on advanced high-precision machining:

✔ CNC Machining (Röders) – Achieves intricate mold details.

✔ EDM & Wire Cut Machines(Makino, Mitsubishi, Charmilles) – Used for deep cavities and fine textures.

✔ Automated Quality Inspection – Real-time IoT monitoring & digital twin technology to maintain consistency.

The result? High-performance molds that produce defect-free parts faster and more efficiently.

4. Design Complexity: The More Features, The Higher the Cost

The complexity of a mold directly impacts its price. Factors that increase cost include:

🔹 Multi-cavity molds – A single-cavity mold makes one part per cycle, whereas an 8-cavity mold increases output but requires precise balancing.

🔹 Undercuts & side actions – Require additional mechanisms like sliders and lifters, adding cost.

🔹 Hot runner systems – Reduce material waste but increase upfront mold investment.

TXS optimizes mold design using DFM (Design for Manufacturing) principles, ensuring efficiency without unnecessary costs.

5. Extensive Testing & Validation: Ensuring Zero Defects

Before mass production, molds must undergo rigorous testing:

🛠️ T-Zero Mass Production Validation – Verifies part quality before full-scale manufacturing.

📊 Injection Parameter Optimization – Uses real-time data & IoT technology to perfect molding conditions.

📏 CMM Inspection & Mold Trials – Ensures every cavity produces parts within specifications.

Without proper testing, molds can fail, leading to expensive delays and production losses.

6. Industry-Specific Compliance & Certification

Certain industries require strict mold validation and certification, which adds cost but ensures regulatory compliance:

🔹 Automotive (IATF 16949) – Ensures molds meet high safety and durability standards.

🔹 Medical (ISO 13485) – Requires 100,000-level cleanroom production for medical-grade plastic components.

🔹 Electronics & Aerospace – Demands precise tolerances and anti-static materials.

TXS is ISO 9001, IATF 16949, and ISO 13485 certified, guaranteeing our molds meet global industry standards.

💰 How to Reduce Injection Mold Costs?

While injection molds are a major investment, smart planning can significantly reduce costs:

✔ Optimize Design for Manufacturing (DFM) – Simplify part design to avoid unnecessary mold complexity.

✔ Leverage Mold Flow Analysis – Detect and eliminate defects before production begins.

✔ Choose the Right Supplier – Work with an experienced, one-stop injection molding partner like TXS to balance cost, quality, and efficiency.

🚀 Looking for a Reliable Injection Mold Manufacturer?

At Tianjin Xuansheng Technology Co., Ltd., we provide:

✅ High-precision mold manufacturing with cutting-edge CNC technology.

✅ Cost-effective injection molding for automotive, medical, electronics, and industrial applications.

✅ End-to-end solutions – From material selection to mold validation and mass production.

📩 Get a Free Consultation Today!

📧 Email: [email protected]

🌐 Website: www.molds-maker.com