What is Overmolding?

Introduction

Overmolding is a specialized injection molding process used to create multi-material, multi-color, or soft-touch plastic components. It is widely utilized in automotive, medical, electronics, and industrial applications to enhance durability, grip, aesthetics, and functionality.

At TXS (Tianjin Xuansheng Technology Co., Ltd.), we specialize in high-precision overmolding solutions, ensuring superior quality and performance for various industries. In this article, we’ll explore what overmolding is, how it works, its benefits, and its applications.

What is Overmolding?

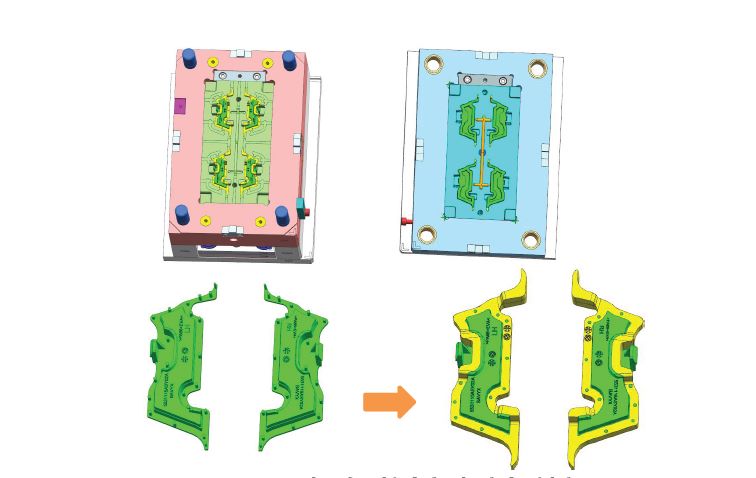

Overmolding is a two-step injection molding process where one material (usually a soft elastomer or rubber-like plastic) is molded over a rigid plastic or metal base. The result is a permanent bond between the two materials, providing additional functionality such as better grip, insulation, or shock absorption.

This process is different from insert molding, which involves placing a pre-formed insert (usually metal) into the mold before injection.

How Does Overmolding Work?

1️⃣ Step 1: Mold the Base Component – The first material, typically rigid plastic (ABS, PC, or Nylon), is molded into the desired shape.

2️⃣ Step 2: Overmolding Process – The base part is placed into another mold cavity, where a second material (such as TPU, TPE, or silicone) is injected over it.

3️⃣ Step 3: Cooling & Solidification – The overmolded part cools, forming a strong mechanical and chemical bond.

4️⃣ Step 4: Quality Inspection – The final product undergoes precision measurement and defect detection using TXS’s advanced inspection systems.

Key Benefits of Overmolding

1. Enhanced Ergonomics & Grip

- The addition of a soft-touch layer improves comfort and usability for handheld products like power tools and medical devices.

2. Improved Durability & Shock Absorption

- Overmolding can provide impact resistance, vibration dampening, and scratch protection.

3. Waterproof & Sealed Components

- Overmolding creates airtight and waterproof seals, making it ideal for medical devices and electronic enclosures.

4. Cost Savings & Production Efficiency

- Reduces the need for secondary assembly and additional fasteners or adhesives.

- Creates aesthetic multi-color and multi-material parts in a single manufacturing process.

5. Strong Bonding Between Materials

- TXS utilizes advanced molding simulation and precision control to ensure flawless adhesion between different materials.

Overmolding vs. Insert Molding: What’s the Difference?

| Feature | Overmolding | Insert Molding |

|---|---|---|

| Process | A second material is molded over an existing part | An insert (usually metal) is placed inside the mold before plastic injection |

| Common Materials | TPU, TPE, Silicone over ABS, PC, Nylon | Metal inserts inside plastic (e.g., brass, steel, aluminum) |

| Bonding Type | Mechanical & chemical bonding | Mechanical interlocking & encapsulation |

| Key Applications | Soft-touch grips, waterproof seals, ergonomic handles | Electrical connectors, threaded inserts, medical devices |

Common Applications of Overmolding

1. Automotive Industry

- Soft-grip handles, gear shifters, and control buttons improve user comfort and aesthetics.

2. Medical Devices

- Surgical grips, syringes, and handheld diagnostic tools benefit from soft, antimicrobial overmolded surfaces.

3. Electronics & Consumer Products

- Smartphone cases, USB cables, and power tools use overmolding for durability and impact resistance.

Why Choose TXS for Overmolding?

At TXS, we provide high-quality, precision overmolding solutions with:

✅ ISO 13485, IATF 16949, and ISO 9001 certifications ensuring global standards.

✅ Advanced molding simulation software to optimize bonding and material selection.

✅ Precision injection molding machines from Germany, Switzerland, and Japan.

✅ Custom solutions for automotive, medical, and electronics industries.

Get a Free Quote Today!

Looking for high-quality overmolding services?

Contact TXS today:

Website: www.molds-maker.com

or Email: [email protected] to discuss your project.

Enhance your products with advanced overmolding—partner with TXS for top-quality solutions! 🚀