High Precision | Engineering Support | Rapid Turnaround

Medical-Grade PEEK Injection Molding Solutions

Engineered for Biocompatibility

Strength & Dimensional Accuracy

Custom-manufactured in ISO 13485 Certified Cleanrooms.

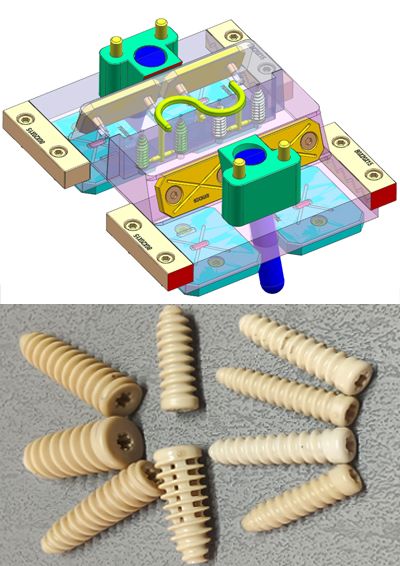

PEEK Interference Screw

Cost Reduction and Efficiency Improvement Solutions

- The product material is PEEK (polyetheretherketone), which is costly, necessitating optimized material utilization.

- Reduce waste generation and lower the production cost through a reasonable design of the mold structure.

- Coordinate with specific production processes to ensure the product quality and functionality.

-

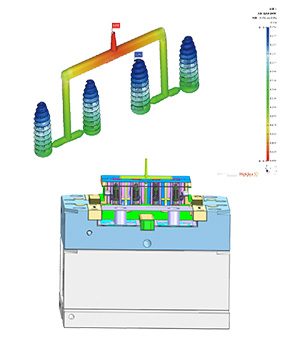

Mold Flow Simulation Analysis: Through advanced molding simulation analysis, optimize the flow balance and achieve the minimum gate weight.

-

Mold Optimization: Design runner and gate systems rationally to reduce scrap generation and improve material utilization efficiency.

-

Specific Production Process: Coordinate with the high-precision injection molding process to ensure the product quality and functionality.

-

Production Cost Control: Significantly reduce overall manufacturing costs.

Why Leading Medical OEMs Choose TXS

TXS is a trusted contract manufacturer specializing in peek injection molding for life-critical medical applications. With Class 100,000 cleanroom facilities, precision tooling, and full regulatory traceability, we deliver implant-grade PEEK components that meet the most demanding international standards for safety, performance, and compliance.

Material Expertise

Biocompatibility You Can Trust

PEEK is non-toxic and chemically inert, making it ideal for long-term implants in orthopedic, spinal, and cranial applications.

Radiolucent & Imaging-Compatible

PEEK enables clear CT/MRI imaging without artifacts, allowing precise implant placement and effective post-op monitoring.

Bone-Like Mechanical Properties

With an elastic modulus similar to cortical bone, PEEK promotes natural load transfer, better bone integration, and fewer implant-related issues.

Cleanroom Manufacturing

We take pride in manufacturing every critical component in ISO-classified cleanrooms. From medical devices to high-precision plastic parts, our controlled environments ensure the highest standards of hygiene, safety, and quality—meeting the strictest requirements of the medical, electronic, and automotive industries.

Precision Mold Fabrication

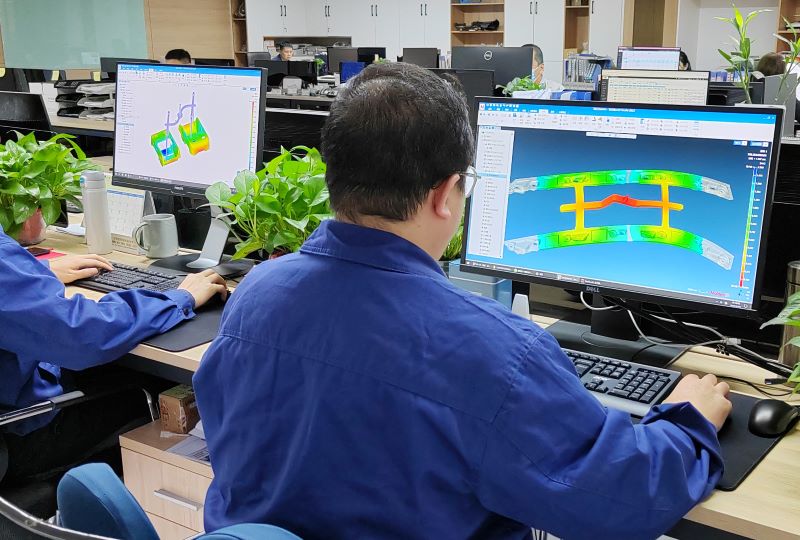

We specialize in high-precision mold fabrication using advanced CNC machining, EDM, and mold flow analysis. Every mold is crafted to micron-level accuracy to ensure optimal performance, durability, and repeatability—empowering your products with unmatched consistency and quality from prototype to mass production.

Simulation + Validation You Can Rely On

We delivers end-to-end engineering assurance through Moldflow simulation, first article inspection, and full documentation support tailored for FDA and CE submissions. Our integrated approach ensures design-for-manufacturability, regulatory compliance, and reduced risk—accelerating your product’s path to market with confidence.

Certified Quality. Trusted by Medical Device Leaders.

At TXS, quality is not just a promise — it’s a certified standard.With an ISO 13485-compliant quality system, a Class 100,000 cleanroom environment, and rigorous quality control processes, we strive to be the preferred manufacturing partner for medical device companies worldwide.From precision molding to final assembly, every step is built on trust, traceability, and compliance.

Certificate

Over 15 Years of Injection Molding for Medical Implants

Customizable Design, From Prototype to Scale-up

Tight tolerance control on thread profiles and core-pin geometry

Factory Scene

Mold Simulation Analysis

High Speed CNC Machines

CNC Machining Workshop

Mirror EDM Machines

Precision Wire-EDM

Mould Spotting Machine

Mold Assembly Workshop

100000 Level Clean Workshop

Plastic Injection Molding

Quality Control Department

Start Your Project Today

Send us your drawing or specifications – our expert team will get back within 24 hours.

Contact Us & Reach !!

Submit inquiry, we will provide you with service 24 hours.

- Shangmatai Industrial Zone, Wuqing District, Tianjin,(Bordering Beijing,Just a 22-minute high-speed rail ride)China

- [email protected]

- (86) 13802197597