- hours: Mon-Fri: 8am – 7pm

- Shangmatai Industrial Zone, Wuqing District, Tianjin,China

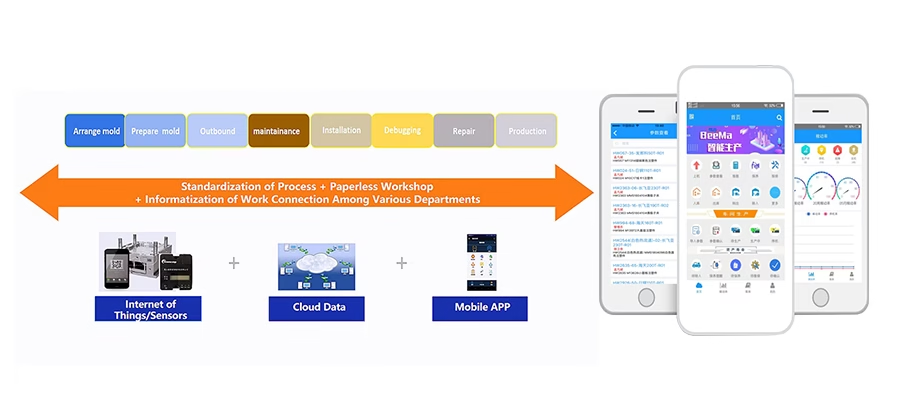

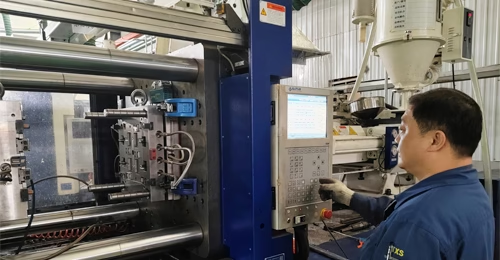

We use T0 mass production system engineering, under the support of high precision 3D model flow simulation analysis and intelligent manufacturing (AIoM) technology, to achieve high quality and efficient injection molding production.

A 100,000-level cleanroom refers to a workshop that can meet high cleanliness requirements during the production process, and its cleanliness level is ISO 1, that is, the particle level is ISO 1. This standard of workshop is usually used in the production process of pharmaceutical, food, electronics, precision machinery and other industries to ensure product quality and safety

Visual Management System

Products cover medical devices, consumables, laboratories…

Using mold flow simulation software, the multi-hole filling balance can be achieved to ensure product quality and high yield, to reach high standards of precision and zero defects.

100k grade clean workshop, 10k grade laboratory

International system certification ISO 13485

Products contain intelligent, consumer electronics

Using molding simulation software, early detection of product defects, such as short shot, suture line, encapsulation, dent, etc., can provide solutions to reduce product variation and optimize the production process

Products include automotive interior and exterior decoration

Use of molding simulation software to assist designers to simulate and verify complex products and molds to avoid potential problems in the early opening period

Rich experience in auto over molding, 2K mold

International system certification IATF16949

Products contain a wide range of industrial

Using molding simulation software can shorten product design time and save manufacturing cost. Product designers or developers can identify potential defects early in product design

We specialize in providing high-precision molds & injection molding solutions

Sed ut perspiciatis unde omniste natus errors volupta accus