How to find a reliable injection mold manufacturer in China?

Searching for a mold manufacturer in China feels like navigating a maze. You face a huge range of prices and promises, making it hard to know who you can trust to deliver quality on time.

To find a reliable Chinese injection mold manufacturer, you must look beyond price. Verify their technical capabilities, check for key certifications like ISO 9001, review past project case studies, and confirm they have strong engineering and project management support. A factory audit is highly recommended.

Finding a great partner isn't just about sending out an RFQ and picking the lowest bidder. It's about building a relationship based on trust and technical competence. I've learned over my career that a thorough vetting process at the start saves incredible amounts of time and money later. Let's walk through the essential steps to identify a truly reliable supplier.

How do you properly evaluate a Chinese mold supplier?

You get a dozen quotes, and they're all over the place. It's tempting to go with a lower price, but you worry about the risks. A bad mold can lead to production delays, poor part quality, and endless headaches.

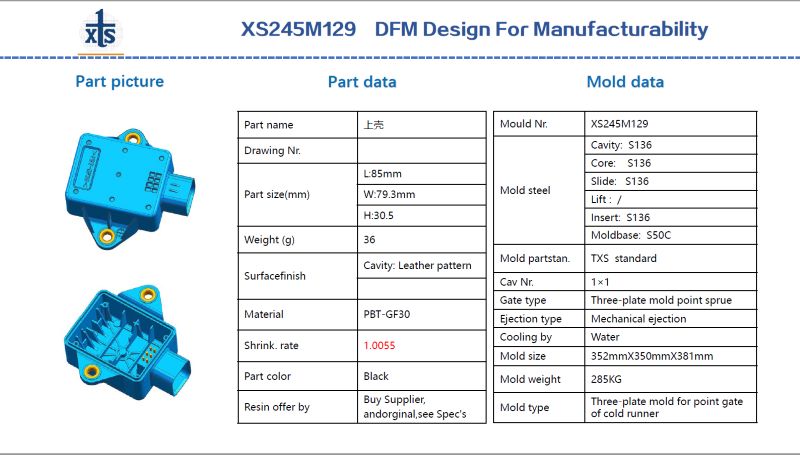

A proper evaluation involves a multi-step process. Start by reviewing their equipment list and certifications. Then, request case studies relevant to your industry. Finally, assess their communication skills and project management process during the quoting stage. A detailed DFM report is a great sign of expertise.

I've developed a checklist over the years to vet potential partners. It goes much deeper than the surface-level information you find on their website. China's mold industry has evolved rapidly. It grew from small, scattered tool shops into the world's largest mold producer. This history created a wide spectrum of suppliers, from basic workshops to advanced, integrated factories. Your job is to find the latter.

Here's what I focus on:

- Technical Capability: Do they have the right tools for the job? I ask for a detailed equipment list. I look for high-precision CNC machines (like Makino or DMG Mori), quality EDMs, and accurate measurement tools (CMM, 3D scanners). This tells me if they can hold the tight tolerances my parts require.

- Quality Systems: Certifications are non-negotiable. For general industrial parts, ISO 9001 is the baseline. For automotive projects, I look for IATF 16949. For medical devices, ISO 13485 is a must. These aren't just pieces of paper; they prove the supplier has robust, repeatable processes for quality control.

- Engineering Depth: A great supplier is a partner, not just an order-taker. I judge their engineering strength by the quality of their Design for Manufacturability (DFM) report. Do they offer real suggestions to improve the part design, or just a basic draft analysis? A company like TXS that uses Moldex3D simulation to predict and solve issues before cutting steel is a huge advantage.

| Vetting Step | What to Look For | Why It's Important |

|---|---|---|

| Initial Screening | Professional website, clear communication, industry experience. | Shows basic professionalism and relevance to your project. |

| Technical Audit | Equipment list, certifications (ISO, IATF), case studies. | Verifies their ability to produce high-quality, compliant molds. |

| Process Review | DFM report quality, project management structure, Moldflow analysis. | Demonstrates engineering expertise and their ability to prevent problems. |

What are the signs of an unreliable supplier?

You're talking to a new supplier and things feel a bit off. The communication is slow, the answers are vague, and the price seems too good to be true. These are red flags that you can't afford to ignore.

Common signs of an unreliable supplier include poor communication, an unwillingness to share information like equipment lists or case studies, a lack of quality certifications, and an unusually low price. They often promise everything without providing any technical evidence to back it up.

I've learned to trust my gut, but I also rely on a concrete list of warning signs. Ignoring them has led to some of my biggest project failures. The goal is to identify these issues early in the vetting process, long before you've sent a deposit. An unreliable partner will cost you far more in the long run than you "save" with a low initial price.

Here are the biggest red flags I watch out for:

- Vague or Slow Communication: If they take days to answer a simple technical question or can't communicate clearly in English, how will they manage complex project details and solve problems during production? Professional suppliers have dedicated project managers.

- No DFM or a Poor One: If a supplier agrees to make a mold without first providing a detailed DFM analysis, run away. They are either not capable of doing it or they don't care about potential manufacturing issues. This is just shifting all the risk to you.

- Resistance to Audits: A reliable factory will be proud to show you their facility, either in person or through a detailed video tour. If they make excuses or refuse a factory audit, they are likely hiding something about their true capabilities.

- The "Yes, Yes, Yes" Attitude: A good engineer knows when to say "no" or "that's not a good idea." A supplier who agrees to every single request without question, especially on difficult features or impossible timelines, likely doesn't understand the complexity and is just trying to win the order. A true partner will challenge you and collaborate to find the best solution.

How do you ensure mold quality throughout the project?

You've chosen a supplier that looks good on paper. Now, how do you make sure the final tool is exactly what you paid for? You can't just place the order and hope for the best.

Ensure mold quality through active project management. This includes approving the final 3D mold design, reviewing weekly progress reports with photos, inspecting steel certificates, and approving T1 samples with a full dimensional report (FCP) and molding parameter sheet.

For me, project management is just as important as the mold-making itself. A great supplier makes this easy because they already have strong internal processes. My role is to stay engaged and hold them accountable at every key milestone. This proactive approach prevents misunderstandings and catches any potential deviations early, when they are easy and cheap to fix.

Here is the typical project flow I follow with a reliable partner:

- Kick-off and Design: We start with a meeting to confirm all specifications. I then review and approve their final 2D and 3D mold designs before any steel is ordered or cut. This is my last chance to catch design errors.

- Manufacturing Updates: I require a weekly progress report. This should include photos of the mold components being machined. It allows me to track the schedule and see the quality of their workmanship in real time. I also ask for the steel certificates to verify they are using the material we agreed on (e.g., H13, not P20).

- T1 Sample Trial: This is the most critical milestone. When the first samples (T1) are produced, I don't just want the parts. I require a complete package: a full First Article Inspection (FAI) report measured by CMM, a video of the mold trial, and the detailed molding parameter sheet. This data tells me if the mold is built to spec and if it runs stables.

This level of oversight ensures there are no surprises at the end of the project. It turns the supplier into a transparent partner and guarantees the quality of the final tool.

Conclusion

Finding a reliable injection mold maker in China is about diligent vetting and active management. Focus on technical capability, proven quality systems, and clear communication to build a successful partnership that goes beyond just price.