Excellent Quality

Custom injection mold Manufacturer

Precision Manufacturing,Expert Solutions,Rapid Turnaround, and End-to-End Digitalization of the Mold Manufacturing Process.

We partner with you to bring your concept to reality with flawless precision.

Plastic Injection Mold Service

With the assistance of advanced mold management system , manages the real-time management from mold design, parts processing, mold assembly and quality management, achieving progress control, cost control , quality control.

Mold Design

- Share your ideas, and our senior design team will provide tailored solutions.

- Reduces mold development time and costs with efficient, high-quality drawings.

- Our team is experienced, passionate, and creative.

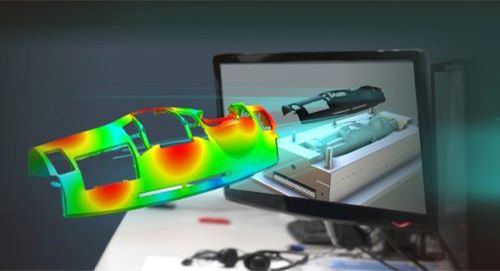

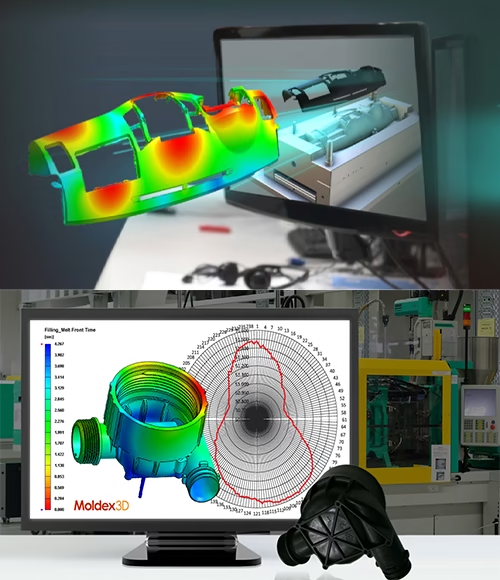

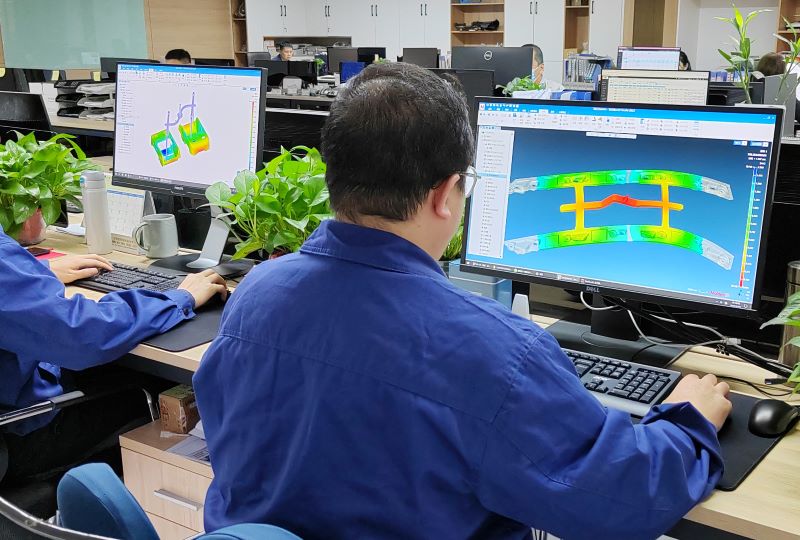

Molding Simulaiton

- Over 8,000 plastic materials in our database.

- Predicts issues and optimizes mold design.

- Identifies potential problems early.

- Refines production parameters.

- Improves product quality and performance.

Mold Manufacturing

Precision Equipment

- Germany Roders CNC: 0.002mm accuracy

- Japan Mitsubishi WEDM: 0.002mm accuracy

- Japan Makino EDM & Switzerland Agie Charmilles EDM

- 200T mold spotting machine

Management System

- TXS Mold Management: Manages the entire process, from order to delivery.

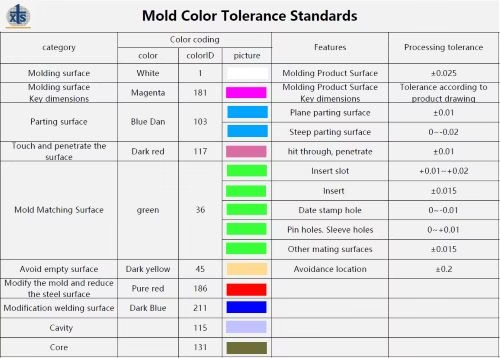

- TXS Color Tolerance System:Control and manage the tolerances of design, processing, and inspection through color.

Mold Quality Control

- Raw material quality inspection: including material analysis, hardness testing, dimensional measurement,surface inspection,etc.

- Processing Quality inspection: including mold parts dimensional measurement, surface inspection, etc.

- Product Quality inspection:including plastic parts dimensional measurement, surface inspection,etc.

Mold Trial & Sampling

- Verify product design feasibility.

- Check mold processing accuracy.

- Identify potential issues and optimize design and manufacturing.

- Reduce production costs and improve quality and efficiency.

Packaging & Shipping

- Inspect according to drawings and checklist.

- Clean, maintain, and apply anti-rust treatment to the mold, then vacuum pack.

- Select the appropriate transportation method: sea, air, or land, based on product nature and destination.

What Sets Us Apart

Material Selection Modification

Are you struggling with material selection or finding that your current materials don’t meet product requirements? Our team of material experts is here to assist you with in-depth analysis and guidance to find the optimal solution.

Product Collaborative Development

We support our customers in ensuring that product and part quality meets industry standards by covering every aspect of the development process. From material selection and process optimization to experimental engineering (DOE), 3D rapid prototyping, and mold & part performance validation, we help streamline the product development cycle and mitigate risks, ensuring a faster time-to-market and higher product reliability.

Molding Simulation

We utilize molding simulation (CAE) analysis to verify designs before mold development and combine rapid mold (MUD) technology to enable fast small-batch testing and validation.

Mold & Molding Engineering Validation

Closely combine material data and simulation technology, provide a series of simulation analysis reports and solutions, predict and solve many questions in the mold design and molding process in advance, greatly shorten the mold development cycle, and improve the success rate of T-Zero mass production

Mold & Molding Integrated Intelligent Manufacturing

Intelligent mold manufacturing capability : With the help of advanced industrial software, the details of tasks such as mold design, parts machining, mold assembly, and quality management are carried out in an orderly manner by using digital processes to achieve real-time progress control and cost control.

High quality injection molding capability : Using advanced IOT technology, the process parameters of the real molding machine and peripheral equipment, molding simulation analysis, and mold design tool software form a data cycle to achieve high-quality production.

Technical Expert Team

Technical team is composed of high-quality technical engineers and technical experts with many years of experience. The core personnel have more than 10 years of experience in the industry, and the expert-level personnel have more than 30 years of experience in the industry.

Intelligent Mold Manufacturing

Leveraging advanced industrial software, we streamline tasks like mold design, parts machining, mold assembly, and quality management. Digital processes ensure efficient real-time progress and cost control throughout production.

Material Selection & Modification

Our experts understand your material needs for simulation analysis and data application, providing comprehensive solutions for product design and modeling in collaboration with our software partners.

● The material measurement laboratory plays a crucial role in material modification, product design, granulation production, mold design, and part molding.

● Through material testing and software services, we assist customers in establishing high-quality material and equipment data, ensuring accurate application in product development, simulation analysis, and manufacturing process validation.

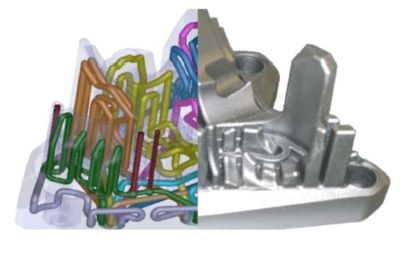

3D Printed Conformal Cooling Channels in Injection Molding

In injection molding, cooling time can account for up to 70% of the total cycle time. This is primarily due to the limitations of traditional mold manufacturing, where cooling channels are typically drilled in straight lines, avoiding structural or assembly components. This severely restricts the design of the cooling system.

By using 3D printing technology to create 3D conformal cooling channels, we can achieve more efficient and uniform cooling, eliminating hot and cold spots. This minimizes temperature-related defects such as residual stress, warping, voids, and dents, providing superior cooling performance.

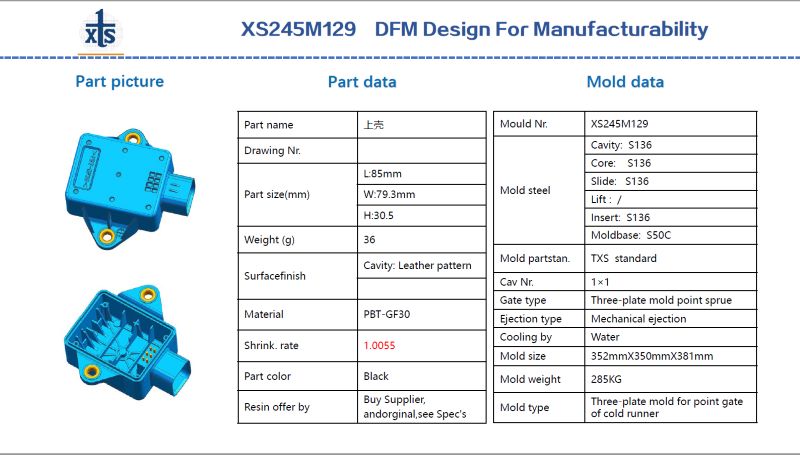

DFM Report

- Identify and resolve early product defects.

- Optimize the mold manufacturing process to reduce costs.

- Enhance product production efficiency.

Molding Simulation

● Virtual Mold Testing: The system performs virtual testing to evaluate various products, gates, runners, cooling channels, and molding conditions.

● Integration of Design and Molding Simulation: Mold design is integrated with molding simulation analysis to predict potential molding issues and defects, optimizing until the best solution is achieved.

● Material Database: Our mold flow simulation system includes a database of over 8,000 plastic materials.

● Risk Reduction and Optimization: Minimize risks in product development, optimize product structure, shorten development cycles, and ensure successful T0 production.

Mold Design

- R&D and Design Team: A dedicated team of experts focused on research and development to drive innovative mold solutions.

- Comprehensive 3D Design: Full-scale 3D design capabilities to visualize and refine every detail of the mold before production.

- Tolerance Management with Color Coding: Precise tolerance management, using color coding for clear, efficient visualization of critical dimensions.

- Automated BOM Generation: Bill of Materials (BOM) automatically generated to streamline the production process.

- Production Capacity: Capable of producing up to 400 sets of molds per year, ensuring high-volume manufacturing efficiency.

Mold Making

Process Analysis and Planning

● Mold Color Tolerance: Tolerance specifications are categorized by color to clearly distinguish the processing requirements and size tolerances for each mold type.

● Mold Management System: A real-time, updated mold tracking system that provides a clear, intuitive overview of project progress and status.

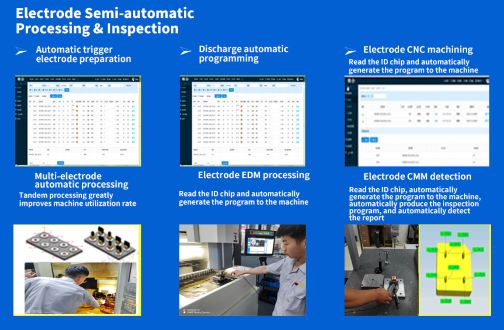

CNC Programming

● Seamlessly integrates with system data.

● Enables automated electrode programming.

● Utilizes advanced 3D cloud computing.

● Optimizes programs for efficiency and security.

● Reduces wait times with background processing.

Parts Processing Equipment Capacity

● CNC Milling Machines

High-end imported equipment, including Roders (Germany).

Precision high-speed CNC milling with machining accuracy of 0.002mm.

● Wire-Cut Discharge

Advanced imported equipment such as Mitsubishi.

Machining accuracy of 0.002mm.

● Electric Discharge Machine (EDM)

Imported premium equipment like Makino and Switzerland GF.

Machining accuracy of 0.002mm.

● Polishing

Ensures mold cavity edges remain intact with no collapse.

Achieves mold surface roughness of SPI-A3.

● Grinding Machine

Precision grinding with machining accuracy of 0.002mm.

● Electrode Semi-Automatic Processing and Inspection

Includes automatic measurement and report generation for quality assurance.

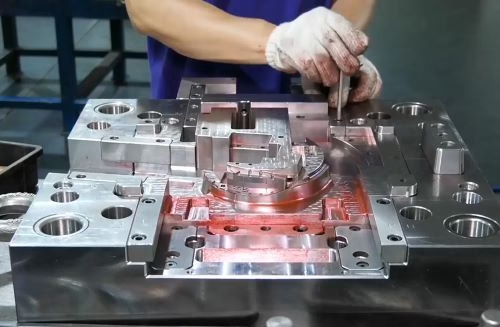

● Mold Assembly

Skilled Assembly Team: Expert mold assembly team with extensive experience.

High Production Capacity: Over 400 molds assembled annually.

Mold Assembly

● Design Feasibility Verification: Ensures the product design is practical and achievable.

● Mold Accuracy Inspection: Confirms the precision of mold processing.

● Identify possible problems and optimize product design and mold manufacturing. Ultimately, production costs are reduced and product quality and production efficiency are improved.

Trial Mold

● Verify the feasibility of product design.

● Check the processing accuracy of the mold.

● Identify possible problems and optimize product design and mold manufacturing.

Ultimately, production costs are reduced and product quality and production efficiency are improved.

Professional Injection Mold & Injection Molding Manufacturer

Molding Simulation Analysis

High Speed CNC Machines

Longmen Processing Center

CNC Engraving Machine

CNC Machining Workshop

Mirror EDM Machines

Precision Wire-EDM

Mould Spotting Machine

Moulds Assembly Workshop

Quality Control Department

TXS provides you vairous classification of plastic injection mould

Mold Class

Cycles

Advantages

Cost

Tolerance

Class 101 Mold

One million or more

● Extremely High-volume Production

● Best mold material

High

±0.02mm

Class 102 Mold

Up to 500,000 times to one million times

● High-volume Production

● Better mold material

Medium

±0.02mm

Class 103 Mold

Under 500000

● Medium-volume Production

● Better mold material

Reasonable

±0.02mm

Class 104 Mold

Under 100000

● Low-volume Production

● Mold material has low wear

Low

±0.02mm

Class 105 Mold

Not exceeding 500

● Prototype Testing

Cheap

±0.02mm

Material Selection Table for Molded Parts

| Plastic | Mold Requirements | Pre-hardened Mold Steel | Hard Mold Mold Steel | High Smoothness Requirements Mold Steel | High Smoothness Alternative Materials | ||

| Anti-corrosion | Wear-resistant | Tensile | |||||

| ABS | No | Low | High | P20 (HRC28-33) | H13 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| ABS+GF | Middle | Middle | High | 738H (HRC35-40) | H13 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| PVC | High | Low | Low | 420H (HRC29-35) | S136 (HRC48-52) | S136 (HRC48-52) | S136H |

| HIPS | No | Low | Middle | P20 (HRC28-33) | 1.2083 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| HIPS+ GPPS | No | Low | Middle | P20 (HRC28-33) | 1.2083 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| GPPS | No | Low | Middle | P20 (HRC28-33) | 1.2083 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| PP | No | Low | High | P20 (HRC28-33) | 1.2083 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| PC | Middle | Middle | High | 420H (HRC29-35) | H13 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| POM | High | Middle | High | 420H (HRC29-35) | S136 (HRC48-52) | S136 (HRC48-52) | S136H |

| SAN | Middle | Middle | High | 420H (HRC29-35) | H13 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| PMMA | Middle | Middle | High | 420H (HRC29-35) | H13 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| PA | Middle | Middle | High | 420H (HRC29-35) | H13 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| LDPE | No | Low | Middle | 420H (HRC29-35) | 1.2083 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

| HDPE | No | Low | Middle | 420H (HRC29-35) | 1.2083 (HRC48-52) | S136 (HRC48-52) | 718/NAK80 |

Contact Us & Reach !!

Submit inquiry, we will provide you with service 24 hours.

- Shangmatai Industrial Zone, Wuqing District, Tianjin,(Bordering Beijing,Just a 22-minute high-speed rail ride)China

- [email protected]

- 0086 -138-0219-7597