Precision Plastic Injection Molding Manufacturer

Standardized Production Workshop ISO 13485

Customized Production On Demand IATF 16949

ISO 9001

TXS Plastic Injection Molding Manufacturing Service

TXS’s injection molding capabilities showcase our extensive production capacity and technical expertise. We guarantee top-quality results by utilizing advanced equipment, optimizing production processes, and enforcing rigorous quality control standards. Committed to continuous innovation, TXS adapts to market demands and leverages the latest in injection molding technology to provide our clients with cutting-edge, reliable solutions.

Technology Areas

Overmolding & Two-Shot Injection Molding

TXS specializes in Overmolding & two-shot injection molding, using advanced molds and equipment to deliver precise, high-quality, multi-material components with consistent results.

Insert Molding

This high-efficiency process is fully supported at TXS with over 30 injection molding machines. Our advanced automation and cooling systems ensure consistent high output and top-quality results.

High-Transparency Injection Molding

Producing transparent parts requires a clean environment and specialized equipment. TXS excels in molding transparent products, using fine-screw injection machines designed for clarity materials. We achieve precision dosing down to 0.02g, working with high-quality materials such as PC, PMMA, COC, PS, ABS, and PEI to ensure excellent transparency and quality.

Multi-Cavity Injection Molding

Multi-cavity molds enable the simultaneous production of multiple identical or different parts. TXS’s advanced production floor, equipped with automation and a 100,000-level clean room, efficiently supports the high-volume demands of multi-cavity molding, ensuring precision and scalability.

Thin-Wall High-Speed Injection Molding

Thin-wall injection molding demands advanced molds and equipment. TXS is capable of producing injection parts with wall thicknesses as low as 0.4mm, making it ideal for high-precision medical testing consumables and large-scale production.

Replacing Steel With Plastic

As materials science advances, the performance of plastic materials has improved significantly, often matching or even surpassing that of metals. Plastics are increasingly replacing metals in industries such as automotive, aerospace, electronics, construction, and healthcare. To reduce costs, improve design flexibility, and achieve weight reduction, many TXS customers have successfully transitioned from metal to plastic, optimizing their products for efficiency and performance.

What Sets Us Apart

Material Selection Modification

Are you struggling with material selection or finding that your current materials don’t meet product requirements? Our team of material experts is here to assist you with in-depth analysis and guidance to find the optimal solution.

Product Collaborative Development

We support our customers in ensuring that product and part quality meets industry standards by covering every aspect of the development process. From material selection and process optimization to experimental engineering (DOE), 3D rapid prototyping, and mold & part performance validation, we help streamline the product development cycle and mitigate risks, ensuring a faster time-to-market and higher product reliability.

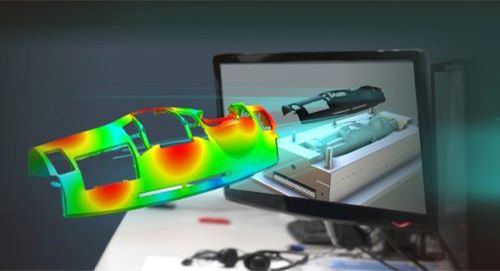

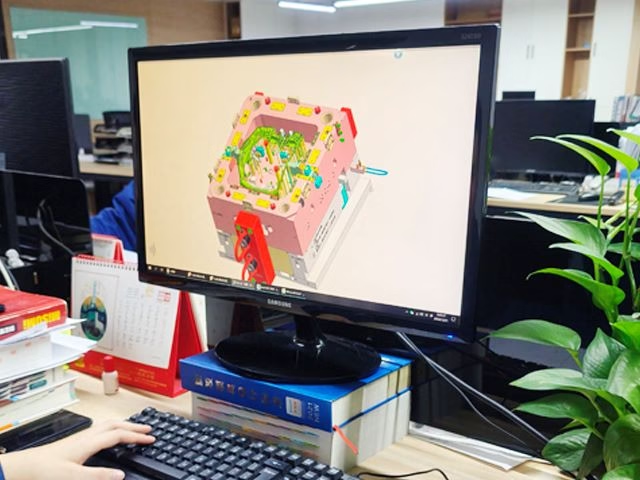

Molding Simulation

We utilize molding simulation (CAE) analysis to verify designs before mold development and combine rapid mold (MUD) technology to enable fast small-batch testing and validation.

Mold & Molding Engineering Validation

Closely combine material data and simulation technology, provide a series of simulation analysis reports and solutions, predict and solve many questions in the mold design and molding process in advance, greatly shorten the mold development cycle, and improve the success rate of T-Zero mass production

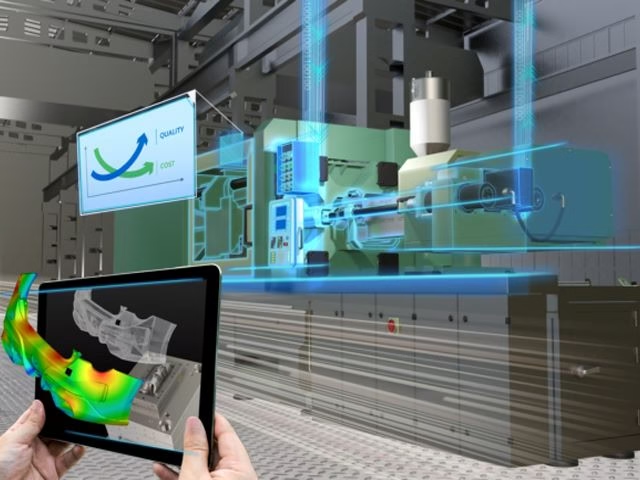

Mold & Molding Integrated Intelligent Manufacturing

Intelligent mold manufacturing capability : With the help of advanced industrial software, the details of tasks such as mold design, parts machining, mold assembly, and quality management are carried out in an orderly manner by using digital processes to achieve real-time progress control and cost control.

High quality injection molding capability : Using advanced IOT technology, the process parameters of the real molding machine and peripheral equipment, molding simulation analysis, and mold design tool software form a data cycle to achieve high-quality production.

Technical Expert Team

Technical team is composed of high-quality technical engineers and technical experts with many years of experience. The core personnel have more than 10 years of experience in the industry, and the expert-level personnel have more than 30 years of experience in the industry.

TXS One-Stop Service Process

01

Send Us Your Project

● 3D or 2D Part Drawings

Preferred 3D Formats: STP / X_T

Preferred 2D Formats: DWG DWF /PDF

● Actual Sample

Ship us an actual sample or prototype.

We can modify the design based on the sample provided.

● Sketch or Draft

We can estimate tooling costs based on your sketch with general dimensions, providing an initial budget estimate.

02

Get Your Quote

Receive a personalized quote for your customized molded parts within 2 days or less. We offer fast, accurate pricing to help you move forward with your project efficiently.

03

Material Selection Modification

Plastic Material Testing & Modification

● Composition Analysis

● Formulation Reduction

● Performance Improvement

● Failure Analysis

● Performance Testing

● Material Research &

● Development

04

3D Printing

● 3D data is generated from samples using scanning technology.

● Samples are tested, and STP drawings are provided.

● Designs are optimized based on requirements.

● A 1:1 physical sample is created for confirmation before mold design.

05

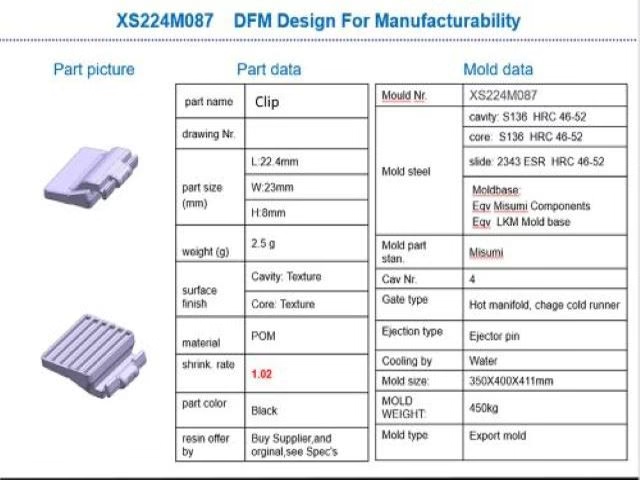

DFM Report

● Solve early product defects.

● Improve mold manufacturing process and reduce mold manufacturing cost

● Improve product production efficiency

06

Molding Simulation Analysis

● Has a database of more than 8,000 plastic materials

● Mold design is leading-in into molding simulaition analysis to predict molding difficulties and defects, and design optimization analysis is carried out until the best solution is obtained.

07

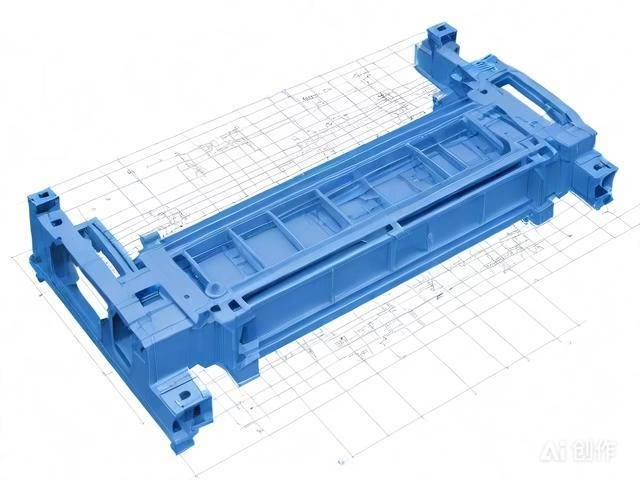

Mold Design

● Our design engineers have extensive experience in export molding.

● Designing various medical products, automotive parts, electrical products, industrial products, etc.

08

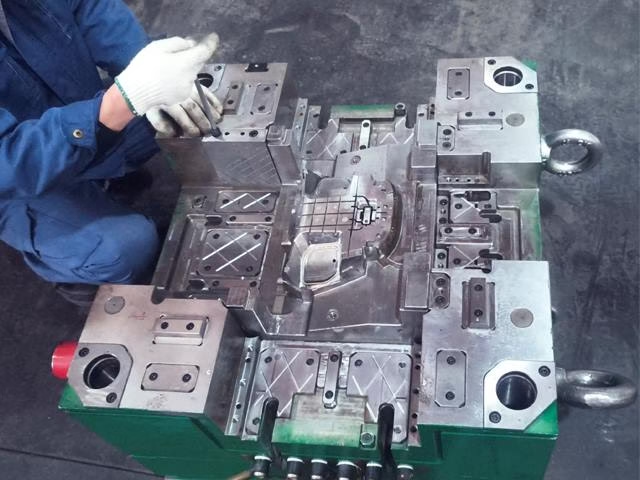

Injection Mold Making

● Process analysis and planning

● CNC programming

●Precision Machining

09

Molds Inspection & Assembly

● Use precision testing equipment to test each step of each part processing

● Experienced mold assembly team

● More than 400 sets of molds made per year

10

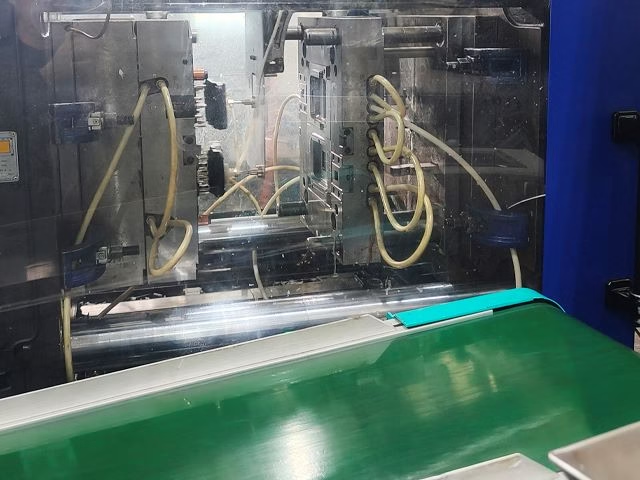

Trial Mold

● Verify the feasibility of product design

● Check the processing accuracy of the mold.

● Identify possible problems and optimize product design and mold manufacturing.

● Ultimately, production costs are reduced and product quality and production efficiency are improved.

11

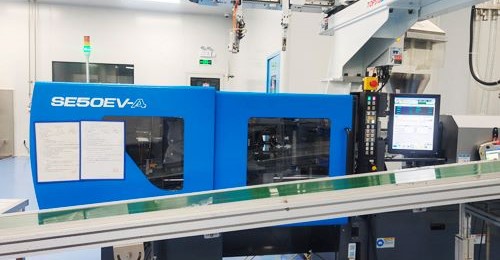

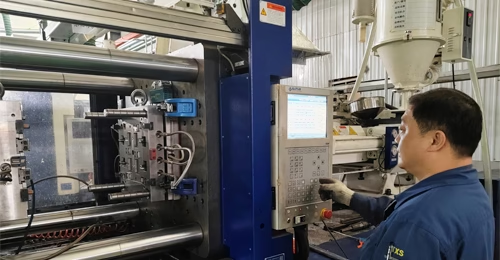

Injection Molding Produce

● Small batch production is available after mold validation.

● Long-term mass production services are offered.

● A visualized management system ensures quality, on-time delivery, and efficiency.

High-precision machines (Sumitomo, Haitian) from 50T to 600T are used.

12

Post Processing

After mass production, Will do post-processing including:

● logo printing

● painting

● plating

● laser engraving

● ultrasonic welding

● etc.

13

Product Assembly & Packaging

● Multiple product assembly services are offered.

● Assembly jigs and lines can be developed for assembled products.

● Packaging design is optimized based on product and shipping requirements.

14

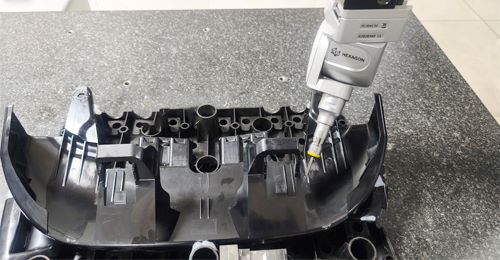

Quality Inspection

● High-end precision testing instruments.

● Experienced team of testing engineers.

15

Delivery

● Strictly package according to the standards and laws and regulations of the target country or region.

● Delivered to you promptly and safely.

Product Appliance

Medical Devices & Consumables

- Our products encompass medical devices, consumables, and laboratory equipment.

- By utilizing mold flow simulation software, we achieve optimal multi-hole filling balance, ensuring high yield, precision, and zero defects.

- 100k Grade Cleanroom

- 10k Grade Laboratory

- ISO 13485 Certification

Smart Home Appliances & 3C Electronics

- We specialize in smart home appliances and consumer electronics.

- Through molding simulation software, we proactively identify defects such as short shots, suture lines, encapsulation, and dents. This allows us to address issues early, minimizing product variation and optimizing the manufacturing process.

Auto Components

- We provide automotive interior and exterior decorative parts.

- Using molding simulation software , we help designers simulate and verify complex products and molds, preventing potential issues during the early stages of production.

- With extensive experience in auto overmolding and 2K molds, we ensure high-quality results.

- IATF 16949 Certification

Industrial Control Product

- We provide a wide range of industrial products.

- With molding simulation software, we streamline the design process, reducing product development time and manufacturing costs. This enables early detection of potential defects, ensuring a smoother, more efficient production cycle.

Focus On Quality Molding Boutique

- 100K Grade Cleanroom

- Visual Management System

- Central Feed System & Waste Gas Treatment

- Post-Processing

TXS offers comprehensive post-processing services to ensure your parts meet the highest quality standards:

- Surface Finishing: Polishing, coating, painting , and texturing

- Assembly

- Laser Engraving & Marking

- Quality Inspection

Injection Molding Workshop

Contact Us & Reach !!

Submit inquiry, we will provide you with service 24 hours.

- Shangmatai Industrial Zone, Wuqing District, Tianjin,(Bordering Beijing,Just a 22-minute high-speed rail ride)China

- [email protected]

- (86) 13802197537