ONE-STOP SERVICE

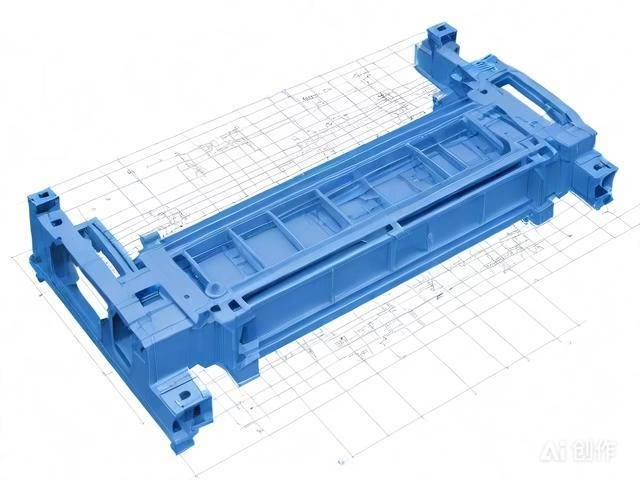

We specialize in delivering high-precision mold and injection molding solutions.

Are you struggling with material selection or finding that your current materials don’t meet product requirements? Our team of material experts is here to assist you with in-depth analysis and guidance to find the optimal solution.

We support our customers in ensuring that product and part quality meets industry standards by covering every aspect of the development process. From material selection and process optimization to experimental engineering (DOE), 3D rapid prototyping, and mold & part performance validation, we help streamline the product development cycle and mitigate risks, ensuring a faster time-to-market and higher product reliability.

Simply provide us with the product or industrial design 3D models you wish to develop, and our team will deliver a comprehensive injection mold development plan tailored to your needs.

Our facility has a 100,000-level medical cleanroom and a high-tech injection molding workshop, and can collaborate with clients to develop automated production line integration to improve efficiency.

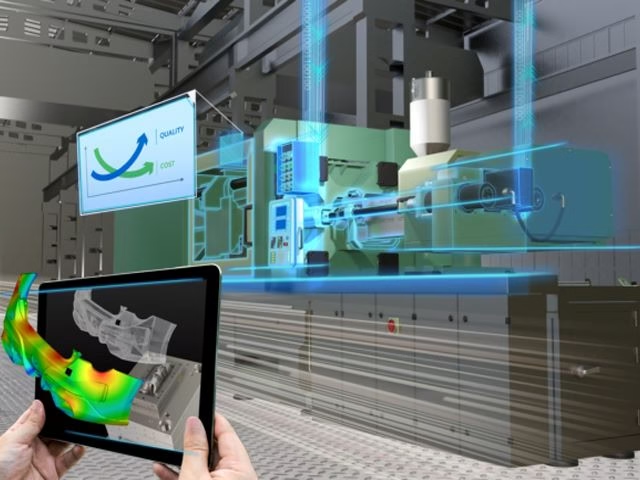

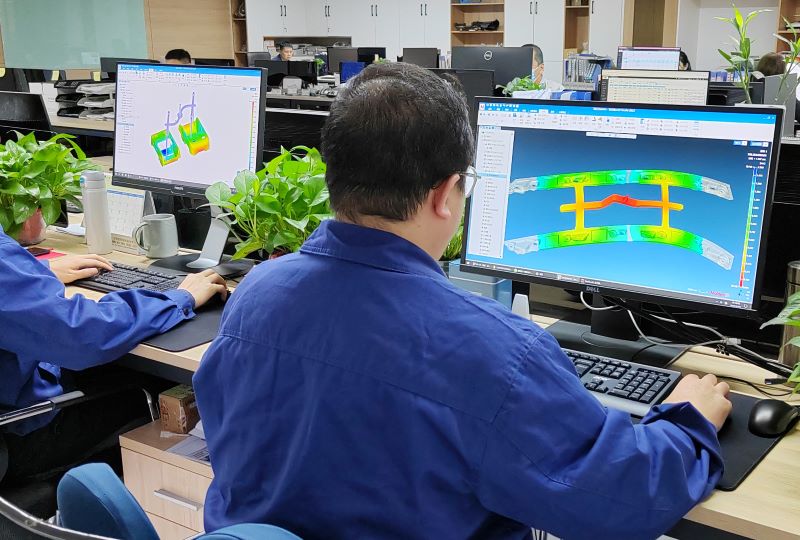

We utilize molding simulation (CAE) analysis to verify designs before mold development and combine rapid mold (MUD) technology to enable fast small-batch testing and validation.

Rapid prototyping is an essential tool in product design and development. It enables designers and engineers to quickly create functional models of their concepts, allowing for early evaluation of feasibility without investing heavily in full-scale production.

This process also facilitates testing different design features to identify the most effective solutions. Rapid prototyping is commonly performed using technologies such as 3D printing, RTV molding, laser cutting, vacuum forming, and CNC milling.

Based on product requirements and to address future market uncertainties, we offer 3D printing resin mold technology and micro-injection mold technology. These solutions enable low-cost mold development, facilitate market scaling, and validate product functionality, providing a solid foundation for the successful mass production of projects.

We are a high-precision CNC service provider offering one-stop solutions for rapid parts customization and small-batch production.

We deliver a range of manufacturing options, from quick-turnaround part customization to efficient small-batch processing, tailored to meet your specific needs.

● High-Quality Molds & Parts

●On-Time Delivery, Ensuring Quality & Quantity

● Free Technical Consultation & Expert Support

● Competitive Pricing

● No Hidden Charges

● 3D or 2D Part Drawings

Preferred 3D Formats: STP / X_T

Preferred 2D Formats: DWG DWF /PDF

● Actual Sample

Ship us an actual sample or prototype.

We can modify the design based on the sample provided.

● Sketch or Draft

We can estimate tooling costs based on your sketch with general dimensions, providing an initial budget estimate.

Receive a personalized quote for your customized molded parts within 2 days or less. We offer fast, accurate pricing to help you move forward with your project efficiently.

Plastic Material Testing & Modification

● Composition Analysis

● Formulation Reduction

● Performance Improvement

● Failure Analysis

● Performance Testing

● Material Research &

● Development

● 3D data is generated from samples using scanning technology.

● Samples are tested, and STP drawings are provided.

● Designs are optimized based on requirements.

● A 1:1 physical sample is created for confirmation before mold design.

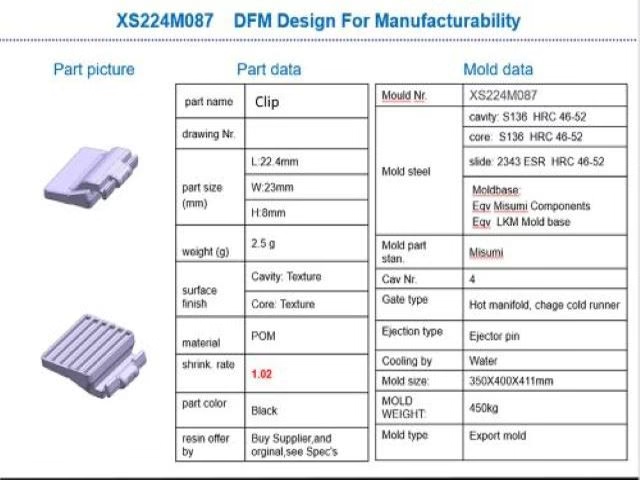

● Solve early product defects.

● Improve mold manufacturing process and reduce mold manufacturing cost

● Improve product production efficiency

● Has a database of more than 8,000 plastic materials

● Mold design is leading-in into molding simulaition analysis to predict molding difficulties and defects, and design optimization analysis is carried out until the best solution is obtained.

● Our design engineers have extensive experience in export molding.

● Designing various medical products, automotive parts, electrical products, industrial products, etc.

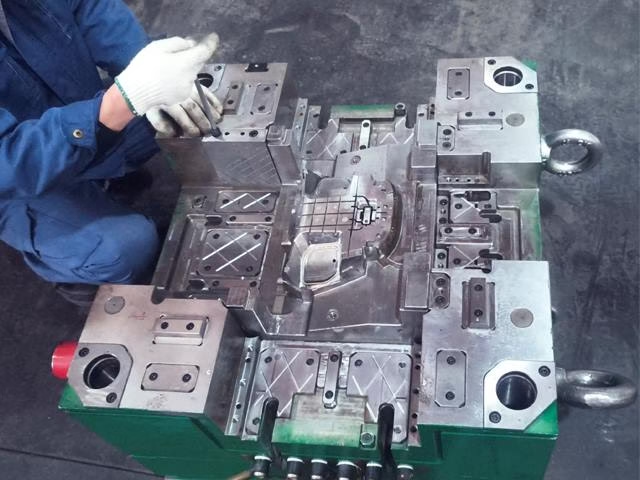

● Process analysis and planning

● CNC programming

●Precision Machining

● Use precision testing equipment to test each step of each part processing

● Experienced mold assembly team

● More than 400 sets of molds made per year

● Verify the feasibility of product design

● Check the processing accuracy of the mold.

● Identify possible problems and optimize product design and mold manufacturing.

● Ultimately, production costs are reduced and product quality and production efficiency are improved.

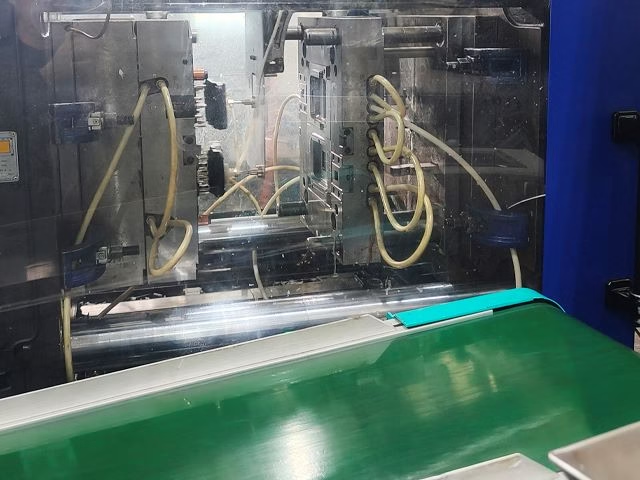

● Small batch production is available after mold validation.

● Long-term mass production services are offered.

● A visualized management system ensures quality, on-time delivery, and efficiency. High-precision machines (Sumitomo, Haitian) from 50T to 600T are used.

After mass production, Will do post-processing including:

● logo printing

● painting

● plating

● laser engraving

● ultrasonic welding

● etc.

● Multiple product assembly services are offered.

● Assembly jigs and lines can be developed for assembled products.

● Packaging design is optimized based on product and shipping requirements.

● High-end precision testing instruments.

● Experienced team of testing engineers.

● Strictly package according to the standards and laws and regulations of the target country or region.

● Delivered to you promptly and safely.

● Collaborative product development

● T-Zero mass production T-Zero

● Intelligent design

● Molding simulation

● National Material Data Laboratory Resources

● Experienced Taiwanese Technical ExpertsTeam

● Digital & Systematic Management for precise mold production.

● 30+ Advanced Machines from Germany、Japan and Switzerland.

● Precision up to 0.005 mm for exceptional mold quality.

● 100,000-Level Cleanroom

● 30+ Injection Molding Machines

●Digital Management System Software

● Sumitomo & Haitian Machines

● 10,000-Level Biological Laboratory

●Swedish Hexagon 3D Coordinate Measuring Machine

● Semi-Automatic Electrode Machining & Inspection

● Dedicated Quality Team

● International Quality Certifications: ISO 13485, IATF 16949, ISO 9001.

● 20+ Years of Team Management Experience

●Advanced Digital Management Systems

● Customer-Focused Approach

● Comprehensive Support:Highly regarded pre-sales, in-sales, and after-sales service by domestic and international clients.

● Non-Disclosure Agreement (NDA)

●Encryption of customer data to ensure confidentiality.

● Employee Access Controls

High-Precision Injection Molding & Mold Manufacturing - One-Stop Custom Solutions

Hello, This is Isabella from TXS-Mold, How can I assist you today?

Chat with us on WhatsApp。

🟢 Online | Privacy policy